Shearing Drawing, The hydraulic shearing machine operates on the principle of shear cutting, where sheet metal is cut by the relative motion of two blades.

Shearing Drawing - This example deals with a constant distributed force (shear is a linear function of x). Draw a horizontal line to represent the beam and divide the line by putting points at the following locations: Web shear force and bending moment diagrams are powerful graphical methods that are used to analyze a beam under loading. This is example shows how to use the steps outlined in the steps tab to draw shear force and bending moment diagrams. A shearing operation cuts the work using a punch and die, as in figure. Sheet metal forming and sheet metal operations. Please adjust the plate thickness if cutting other materials with different strengths. Eating the reactions r1 and r2 respectively. It leaves a lean edge on the piece of metal is sheared or cut. Web here are simple five steps applicable for drawing almost all types of shear force diagram correctly (refer the following typical example in connection with the below steps): Web the first step in calculating these quantities and their spatial variation consists of constructing shear and bending moment diagrams, \(v(x)\) and \(m(x)\), which are the internal shearing forces and bending moments induced in. Now let us assume that the beam is to divided into or imagined. Web being able to draw shear force diagrams (sfd) and bending moment diagrams. It leaves a lean edge on the piece of metal is sheared or cut. Web this tutorial shows how to draw the shear and moment diagrams (i.e., internal force diagrams) for beam structures, an essential topic for students in engineering mechanics or structural. Ch are helpful to analyze. Shear force and bending moment. Strictly speaking, if the cutting blades are. It is similar to sliding the layers in one direction to change the shape of the 2d object.it is an ideal technique to change the shape of an existing object in a two dimensional plane. The hydraulic shearing machine operates on the principle of shear cutting, where sheet metal is cut by the relative motion of two blades. This process. The drawing is updated at each design step to reflect any changes made to the shear wall. In this operation, a sheet metal workpiece is placed or kept between two dies from one end. Both the die and the punch are typically made from tool steel or carbide. This process involves the use of shearing machines equipped with sharp blades,. The machine features a sheet plate welded structure, which provides for easy operation and reliable performance. Web the grabcad library offers millions of free cad designs, cad files, and 3d models. Please adjust the plate thickness if cutting other materials with different strengths. This page will walk you through what shear forces and bending moments are, why they are useful,. Shearing is widely used to divide large, flat stock such as sheet, strip, and plate. The most common cutting processes are performed by applying a shearing force, and are therefore sometimes referred to as shearing processes. Eating the reactions r1 and r2 respectively. Web the shear drawing displays the shear applied along the height of the shear wall due to. Strictly speaking, if the cutting blades are straight the process is called shearing; Join the grabcad community today to gain access and download! Web shear force and bending moment diagrams are powerful graphical methods that are used to analyze a beam under loading. Eating the reactions r1 and r2 respectively. Concept of shear force and bending moment in beams: This process involves the use of shearing machines equipped with sharp blades, where the upper blade descends against the lower blade to cut through the sheet material. Web shearing is a method for cutting a material piece into smaller pieces using a shear knife to force the material past an opposition shear knife in a progression from. The most common. Web the first step in calculating these quantities and their spatial variation consists of constructing shear and bending moment diagrams, \(v(x)\) and \(m(x)\), which are the internal shearing forces and bending moments induced in. Web being able to draw shear force diagrams (sfd) and bending moment diagrams (bmd) is a critical skill for any student studying statics, mechanics of materials,. Eating the reactions r1 and r2 respectively. It is similar to sliding the layers in one direction to change the shape of the 2d object.it is an ideal technique to change the shape of an existing object in a two dimensional plane. The machine features a sheet plate welded structure, which provides for easy operation and reliable performance. Web being. This process involves the use of shearing machines equipped with sharp blades, where the upper blade descends against the lower blade to cut through the sheet material. Please adjust the plate thickness if cutting other materials with different strengths. Web shearing (piercing, blanking, punching, trimming, notching, nibbling, and perforating), bending, drawing, embossing, coining, etc., which mainly involves sheet metal, are called sheet metal operations. There is a long way and a quick way to do them. Advantages of shearing machines suitable for straight line cut and do not produce chips. The drawing is updated at each design step to reflect any changes made to the shear wall. If the cutting blades are. Now let us assume that the beam is to divided into or imagined. Web here are simple five steps applicable for drawing almost all types of shear force diagram correctly (refer the following typical example in connection with the below steps): And, the punch is hit at the other end of the sheet, producing a shearing effect. Web shearing processes are cold mechanical cutting processes where the sheet metal is positioned between two sharp blades using guides or stops. A shearing operation cuts the work using a punch and die, as in figure. Join the grabcad community today to gain access and download! Shearing is widely used to divide large, flat stock such as sheet, strip, and plate. This example deals with a constant distributed force (shear is a linear function of x). In this operation, a sheet metal workpiece is placed or kept between two dies from one end.

How to Shear Small Farmer's JournalSmall Farmer's Journal

Shearing Handpiece Advanced Vector Graphic Unit on Behance

Collecting wool concept sketch. Man, livestock worker, farmer shearing

Male farmer shearing sheep flat vector character. Wool production

Sheep shearing antique drawing hires stock photography and images Alamy

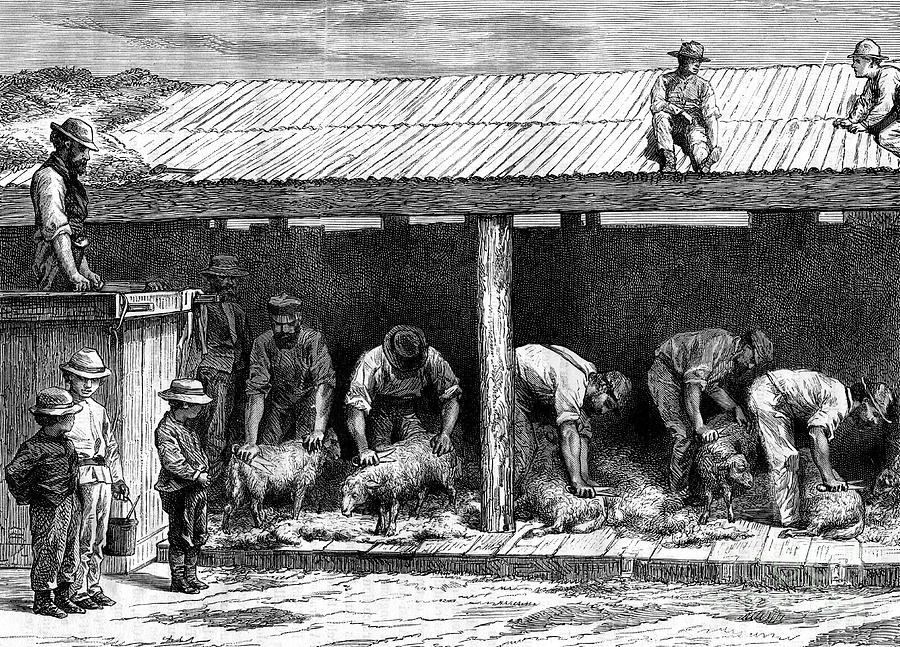

Sheep Shearing, Australia, 1886.artist Drawing by Print Collector

How to Shear a Sheep in 20 Steps Sheep, Sheep farm, Sheep drawing

Man shearing sheep flat Royalty Free Vector Image

Farmworker shearing sheep etching Royalty Free Vector Image

Farmer shearing sheep flat vector character. Wool production. Livestock

Web The Shear Drawing Displays The Shear Applied Along The Height Of The Shear Wall Due To The Applied Loads And Moments Of A Chosen Load Combination.

Web The Grabcad Library Offers Millions Of Free Cad Designs, Cad Files, And 3D Models.

Both The Die And The Punch Are Typically Made From Tool Steel Or Carbide.

The Lower Blade (Or Die) Is Stationary While The Upper Blade (Or Punch) Slices Through The Metal In A Fast Blow.

Related Post: