Drawing For Manufacturing, When possible draw parts to a 1:1 scale and print to get a real sense of size.

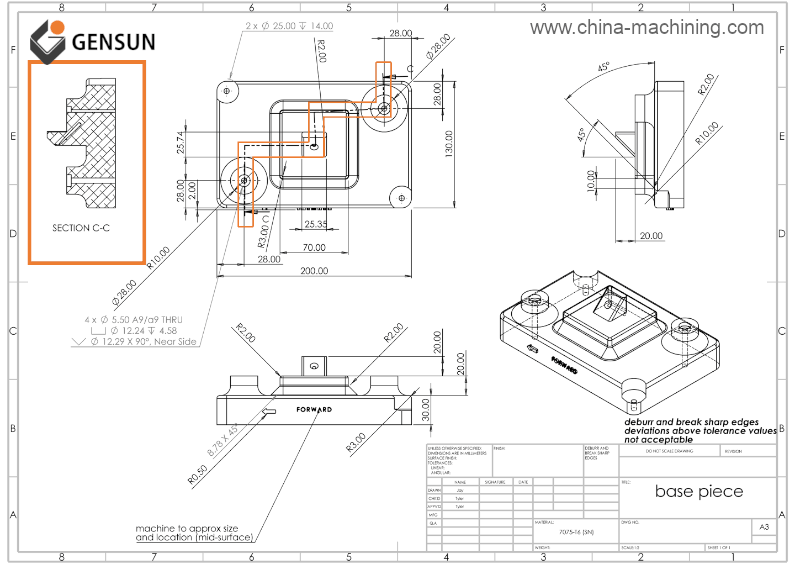

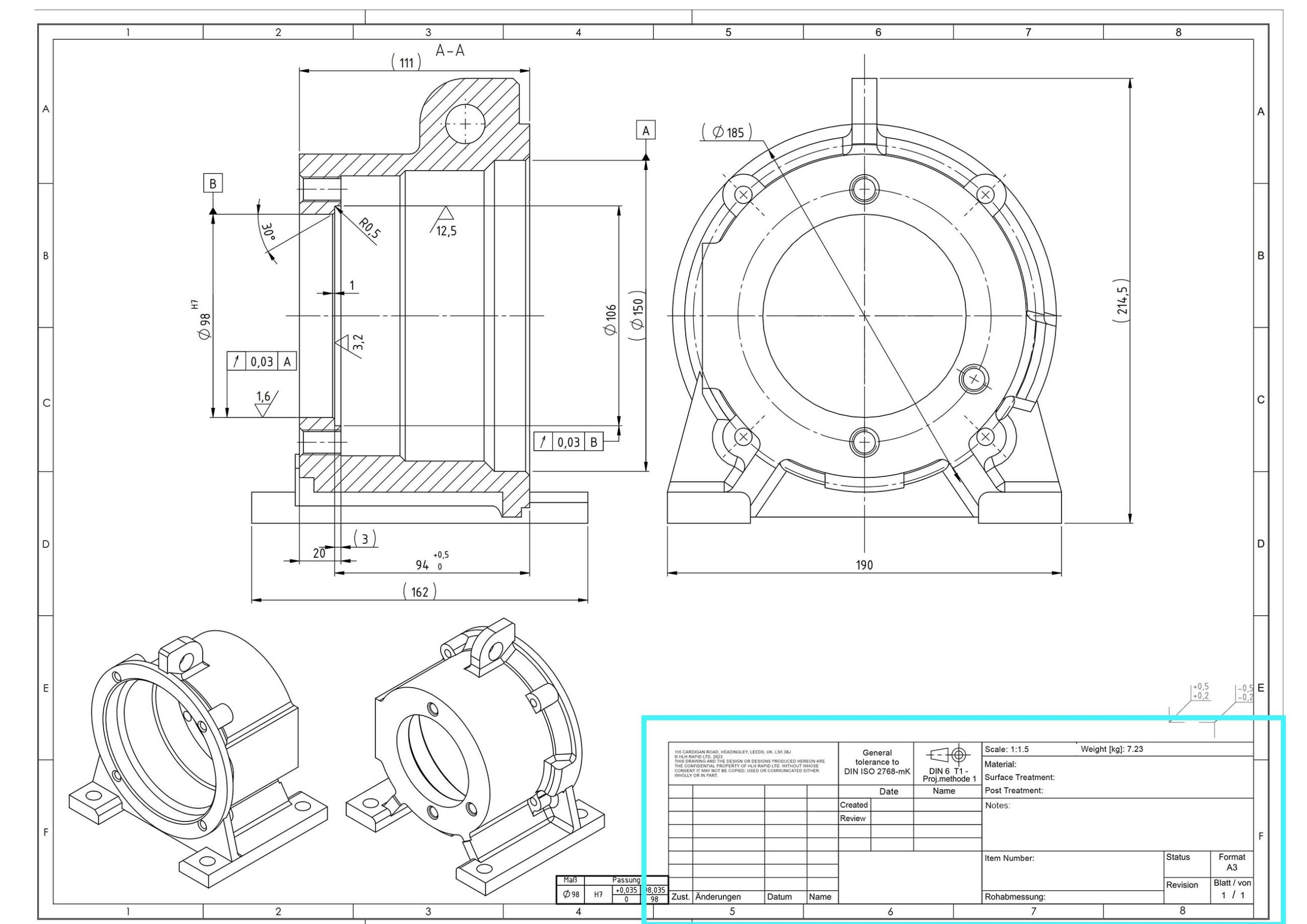

Drawing For Manufacturing - The first step of the gd&t process is dimensioning the orthographic views you added to the drawing. To completely describe the parts, both visually and dimensionally; The purpose of this guide is to give you the basics of engineering sketching and drawing. Web in this article we will cover the basics of creating high quality engineering drawings for individual part designs so that you can communicate your design and manufacturing intent clearly, as well as review other drawings effectively. Web engineering drawings are the most important deliverables that a design engineer produces. Web “design for manufacturability” is also known as “design for manufacturing,” or “dfm.” it is the process of designing a part or assembly with its manufacturing process in mind. This makes understanding the drawings simple with little to no personal interpretation possibilities. But many product developers may not know how those files are used on the shop floor. Web how to create a technical print from scratch. We will treat “sketching” and “drawing” as one. Web thus, this article provides a complete overview of technical drawing in the machining industry, including its importance, the common drawing standards and conventions, and tips for creating accurate and effective engineering drawings. We will treat “sketching” and “drawing” as one. To show the parts in assembly; To identify all the parts; Engineering drawings use standardised language and symbols. Web engineering drawings are the most important deliverables that a design engineer produces. Web fabrication drawings, also known as detail drawings, are a type of technical drawing that provides detailed information for the manufacturing, assembly, and construction of a product or structure. As a seasoned professional in the cad/cam industry with over a decade of experience, my team at kalp. Web an engineering drawing (also named as mechanical drawing, manufacturing blueprints, drawings, dimensional prints, and more) refers to one of the technical drawings, which helps to define engineering products’ requirements. Web deep drawing is the process of drawing sheet metal blank into a desired shape. But bad drawings will make you look like a bad engineer, and parts made from. This makes understanding the drawings simple with little to no personal interpretation possibilities. Engineering drawings use standardised language and symbols. Web thus, this article provides a complete overview of technical drawing in the machining industry, including its importance, the common drawing standards and conventions, and tips for creating accurate and effective engineering drawings. Sheet metal drawing and wire, bar, and. Usually, a number of drawings are necessary to completely specify even a simple component. Our proficiency in autocad, solidworks, and other. Web in this article we will cover the basics of creating high quality engineering drawings for individual part designs so that you can communicate your design and manufacturing intent clearly, as well as review other drawings effectively. A common. Use clear and concise dimensioning practices. The purpose is to convey all the information necessary for manufacturing a product or a part. As the material is drawn (pulled), it stretches and becomes thinner, achieving a desired shape and thickness. Web “design for manufacturability” is also known as “design for manufacturing,” or “dfm.” it is the process of designing a part. But many product developers may not know how those files are used on the shop floor. Web 56 freelancers are bidding on average £115 gbp for this job. Web deep drawing is the process of drawing sheet metal blank into a desired shape. These best practices apply to 2d drafting and creating technical drawings from a 3d model. When possible. As a seasoned professional in the cad/cam industry with over a decade of experience, my team at kalp is ready to provide you with the comprehensive 3d cad drawings your manufacturing project needs. Use clear and concise dimensioning practices. But many product developers may not know how those files are used on the shop floor. Web technical drawings are used. Consult the manufacturer before producing detailed drawings. Sheet metal drawing and wire, bar, and tube drawing. Web thus, this article provides a complete overview of technical drawing in the machining industry, including its importance, the common drawing standards and conventions, and tips for creating accurate and effective engineering drawings. Web technical drawings are used in various fields, such as engineering,. Choose standard templates like astm, iso, and din templates as they are more commonly used and understood by machinists and manufacturers across. An engineering drawing is a type of technical drawing that is used to convey information about an object. Web how to create a technical print from scratch. This is especially true for the engineer. Sheet metal drawing and. Web 56 freelancers are bidding on average £115 gbp for this job. They provide all the instructions needed to make your parts exactly as you intended. This makes understanding the drawings simple with little to no personal interpretation possibilities. The first step of the gd&t process is dimensioning the orthographic views you added to the drawing. One of the best ways to communicate one’s ideas is through some form of picture or drawing. Usually, a number of drawings are necessary to completely specify even a simple component. This process is significantly simpler now that most of the geometric information is contained in your solid model. “sketching” generally means freehand drawing. While the former is required to manufacture the components correctly, the latter ensures that these components help the mechanical, electrical, and plumbing units to function seamlessly. These best practices apply to 2d drafting and creating technical drawings from a 3d model. Web drawing is a manufacturing process that uses tensile forces to elongate metal, glass, or plastic. Requirements to the set of drawings: Drawing is classified into two types: As a seasoned professional in the cad/cam industry with over a decade of experience, my team at kalp is ready to provide you with the comprehensive 3d cad drawings your manufacturing project needs. The purpose of this guide is to give you the basics of engineering sketching and drawing. Web combining manufacturing and engineering drawings is necessary for the success of any construction project.

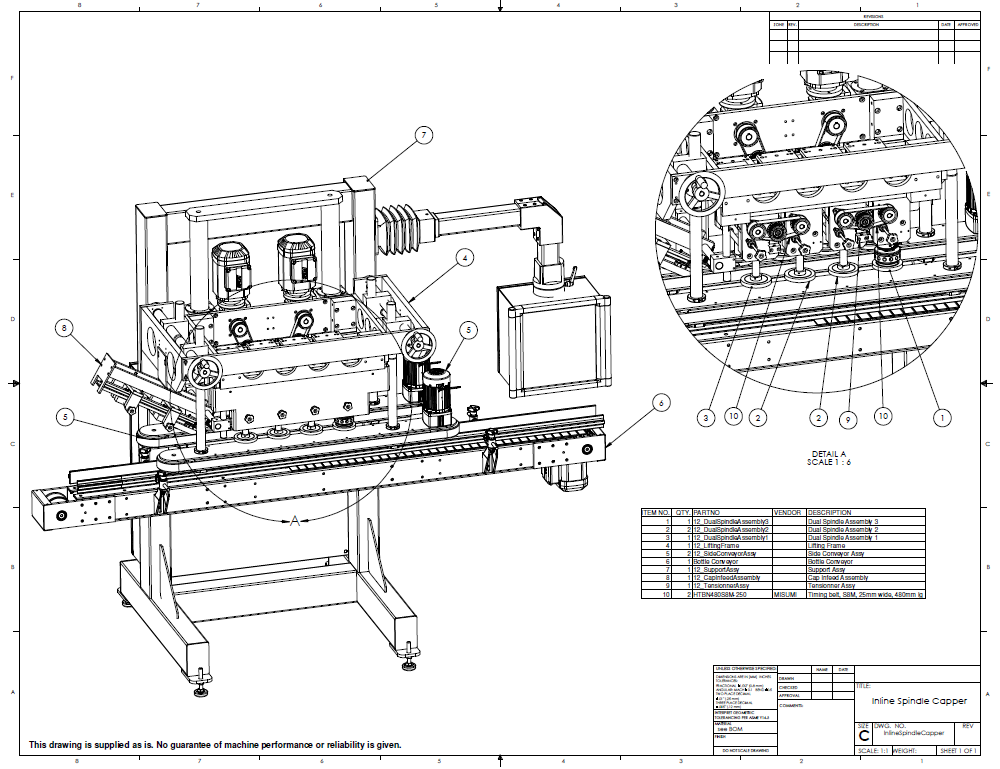

Machining Drawing at Explore collection of

The best free Manufacturing drawing images. Download from 78 free

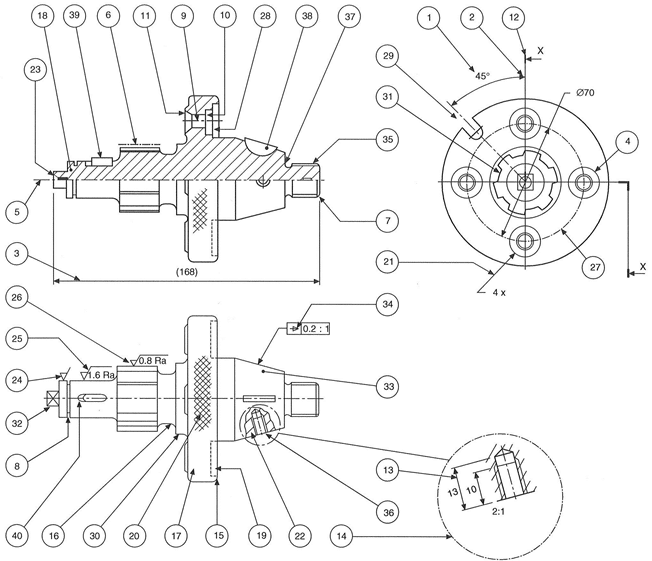

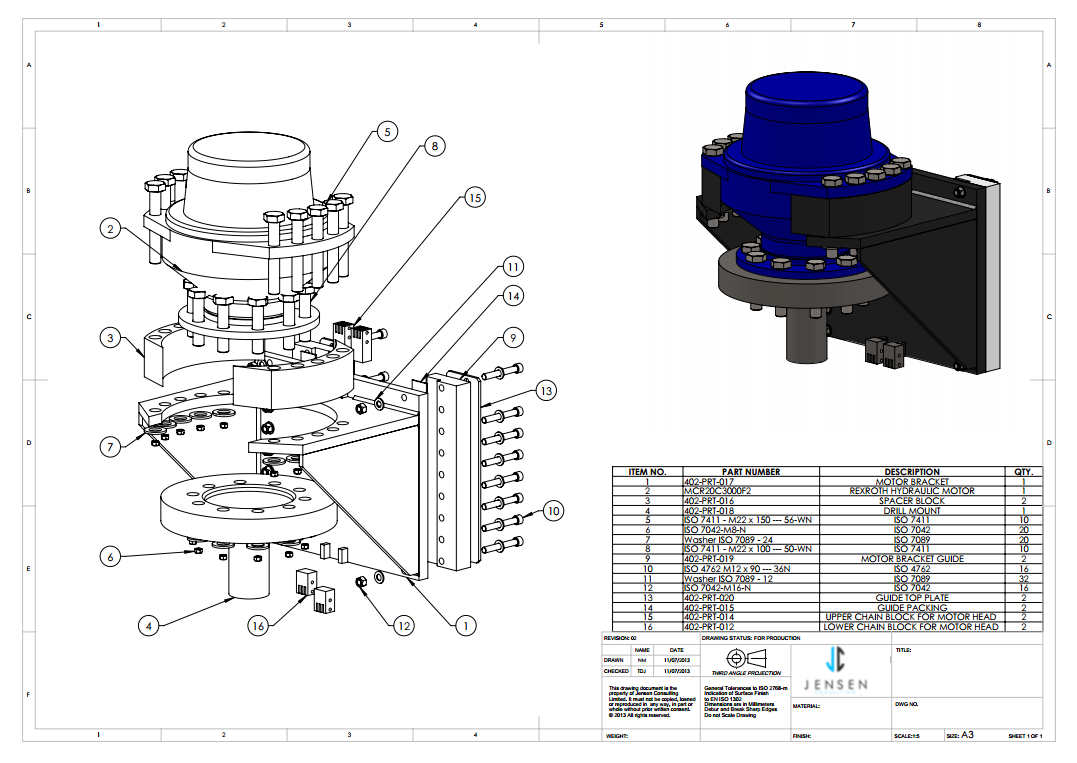

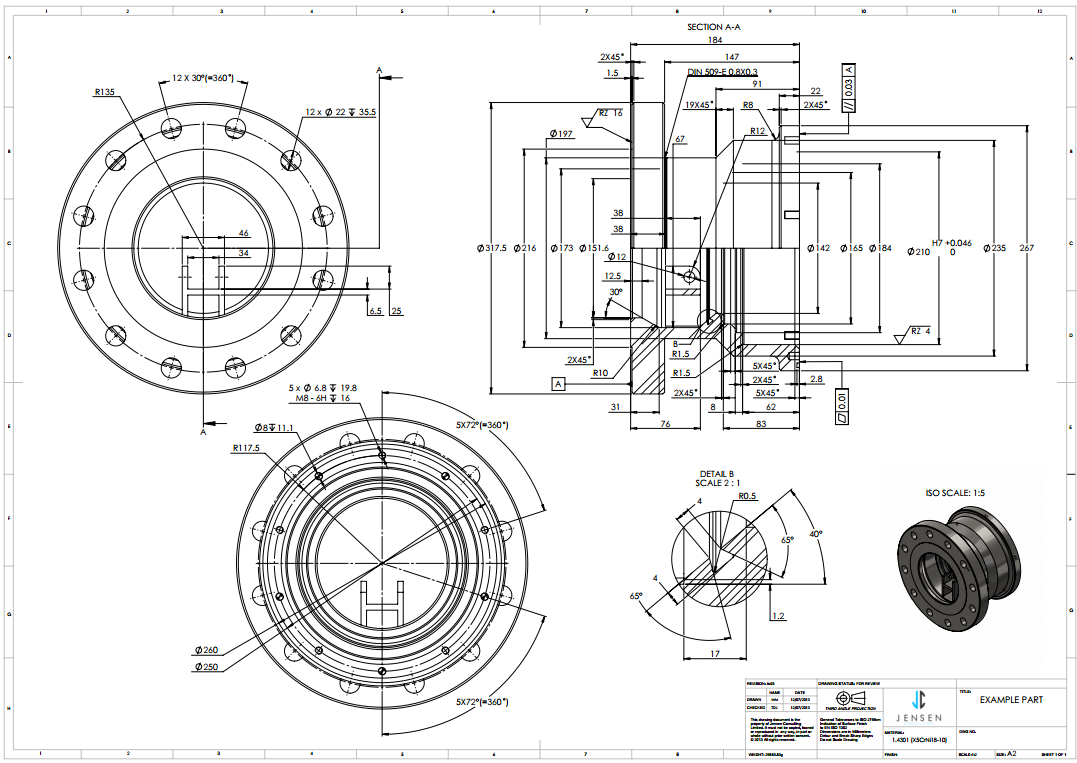

The requirements of machine drawings (Manufacturing Drawings) Jensen

Manufacturing Drawing at Explore collection of

Industrial Drawings at Explore collection of

Manufacturing Drawing at Explore collection of

How to Create Great Technical Drawings in Manufacturing

2D Technical Drawings CNC Machining Service

How to prepare a technical drawing for CNC machining Hubs

Manufacturing drawing/ 2D technical drawings with detailed GD&T and BOM

In Those Cases, We Have Very Powerful Tools Available To Us.

Sometimes Using Main Orthographic Views Is Impossible To Show All The Features Of An Object To The Degree That The Object Is Sufficiently Described For Manufacturing.

To Identify All The Parts;

This Is Especially True For The Engineer.

Related Post: