Deep Drawing, This method utilizes both tensile and compressive forces, under high pressure, to achieve precise and consistent results while maintaining the thickness of the material.

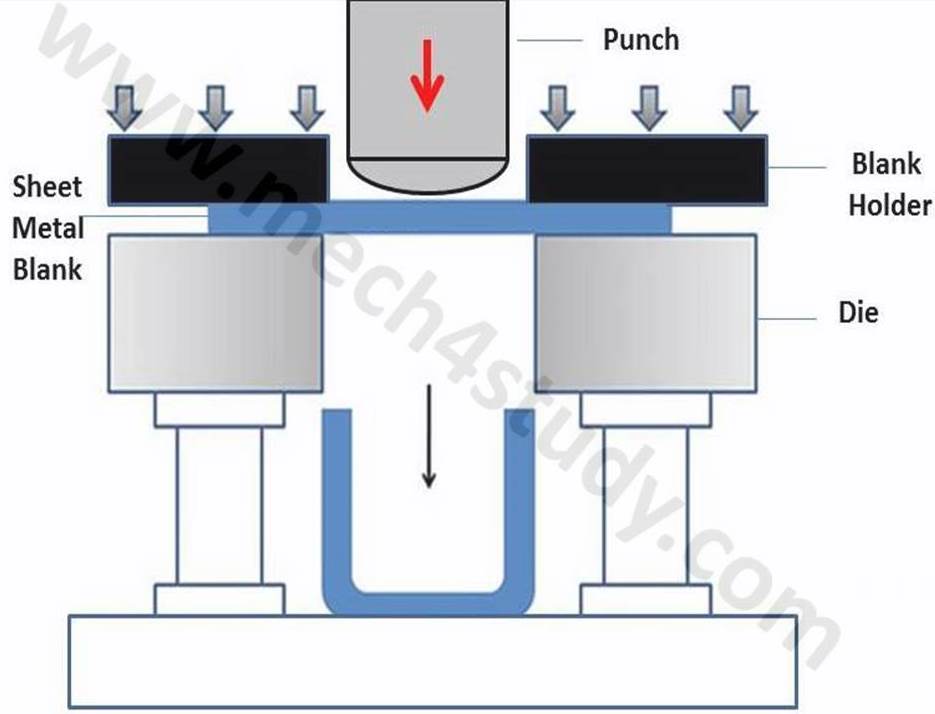

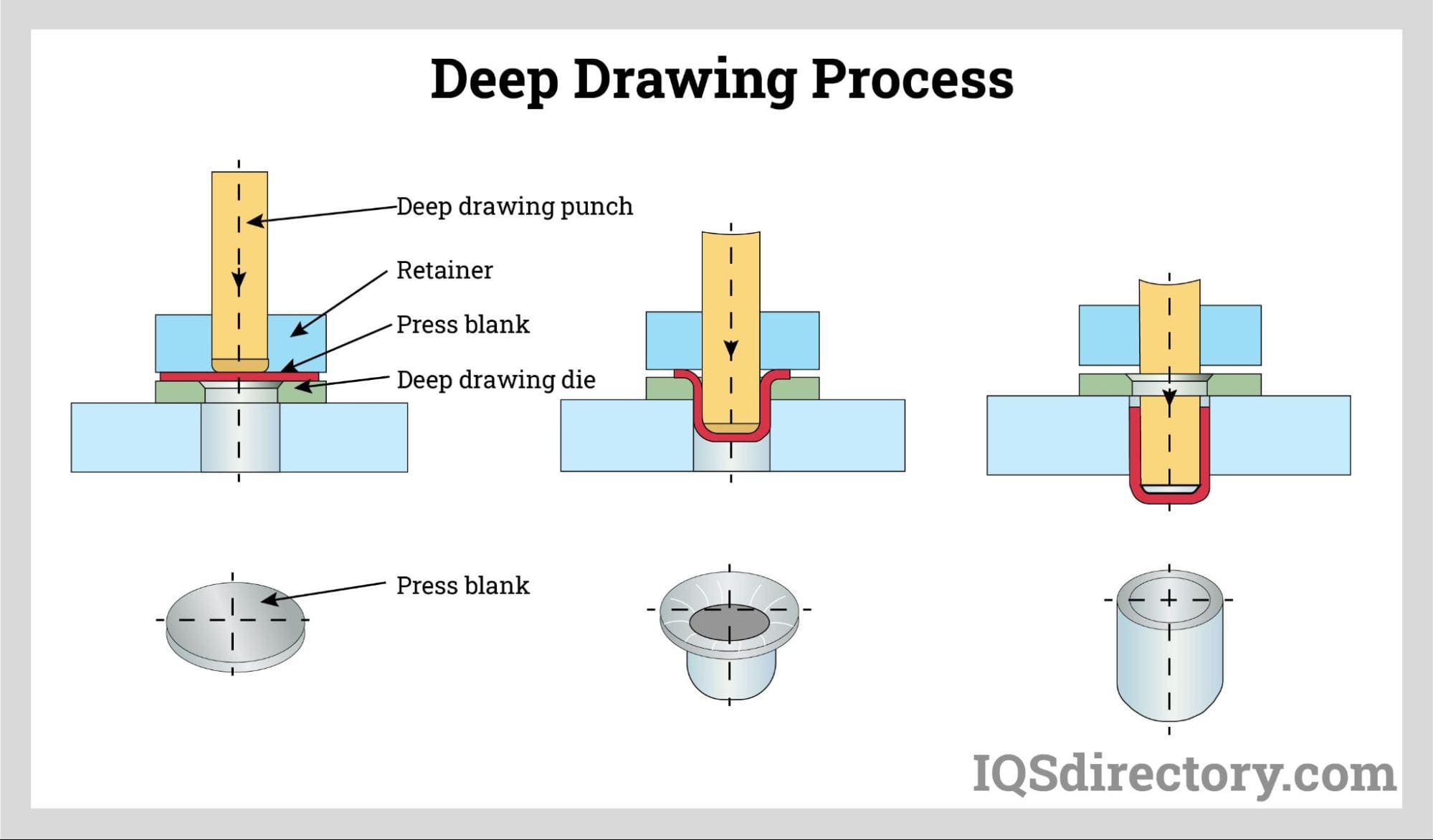

Deep Drawing - Initially, the blank is heated to plastic state and it is placed over the die as shown in figure 1. Web 07/31/2024 july 31, 2024. Web deep drawing (in the context of sheet metal forming) is the process by which a flat sheet of steel is transformed into a deep (often complex) shape, whereby the flat sheet is “drawn in” from the edges and “sucked in” to create a deep shape that otherwise may not be possible using normal metal forming techniques. Deep drawing is a frequently used process of forming technology, which is regulated in din 8584. Many cylindrical parts like metal can, pots, container for food and beverages, kitchen sinks, automobile fuel tank etc. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Web according to din 8584, deep drawing is a tensile compression metal forming process, which shapes a sheet metal blank as a hollow body open on the one side or of a projected hollow body to one with a smaller cross section, without intentionally modifying its. Web deep drawing is a process of converting metal sheet into cylindrical or box shaped structure with or without changing its length and thickness. Web deep drawing is a sheet metal forming process that involves complex material flow and force distributions. Web minnesota vikings quarterback sam darnold (14) under center during the first day of the teams training camp at tco performance center in eagan on wednesday, july 24, 2024. This operation entails a metal sheet being stretched over a die. Web deep drawing is a process of converting metal sheet into cylindrical or box shaped structure with or without changing its length and thickness. In this lesson, professor metal explains how deep drawing, multiple deep draws and hydroforming produce metal cups, cans, pans, domes and shaped metal products. It. Web well, bless her heart! It is thus a shape transformation process with material retention. Deep drawing involves stretching the metal blank around a plug and then moving it into a moulding cutter called a die. Deep drawing is a metal forming process used to create hollow, seamless parts with a depth greater than their diameter by drawing a sheet. Web the kraken have a few trade candidates on the roster. Web what is deep drawing? In some cases, material hardening during deformation can increase the strength of parts. Web this article endeavors to demystify the intricate domain of sheet metal drawing, focusing specifically on its more specialized variant, deep drawing. Deep drawing is a metal forming process used to. Web welcome to this comprehensive guide on deep drawing, a process integral to the world of metal forming. Limitations of deep drawing sheet metal. Web deep drawing is one of the most widely used processes in sheet metal forming, in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Deep. Web deep drawing is a sheet metal forming process by which a sheet metal blank is slightly clamped along its perimeter by a blank holder and radially drawn into a forming die by use of a punch. Web this article endeavors to demystify the intricate domain of sheet metal drawing, focusing specifically on its more specialized variant, deep drawing. Web. Deep drawing involves stretching the metal blank around a plug and then moving it into a moulding cutter called a die. Web according to din 8584, deep drawing is a tensile compression metal forming process, which shapes a sheet metal blank as a hollow body open on the one side or of a projected hollow body to one with a. Aug 1, 2024 at 12:34 am et. Factors affecting the cost of deep drawing sheet metal. Deep drawing produces shapes that are uniform and seamless, reducing potential weak points in the finished part. Web deep drawing is the process of forming a metal part from sheet stock, or a metal blank. Deep drawn parts have a high degree of consistency. Deep drawing involves stretching the metal blank around a plug and then moving it into a moulding cutter called a die. Web according to din 8584, deep drawing is a tensile compression metal forming process, which shapes a sheet metal blank as a hollow body open on the one side or of a projected hollow body to one with a. With the punch, you push the metal into the die cavity. Deep drawing involves stretching the metal blank around a plug and then moving it into a moulding cutter called a die. Web deep drawing is a sheet metal forming process that involves complex material flow and force distributions. Web deep drawing is one of the most widely used processes. Deep drawing produces shapes that are uniform and seamless, reducing potential weak points in the finished part. In this lesson, professor metal explains how deep drawing, multiple deep draws and hydroforming produce metal cups, cans, pans, domes and shaped metal products. Perhaps one of the biggest misconceptions about deep drawing is that the metal is stretched into the part geometry.. With the punch, you push the metal into the die cavity. Web deep drawing is a sheet metal forming process by which a sheet metal blank is slightly clamped along its perimeter by a blank holder and radially drawn into a forming die by use of a punch. Web what is deep drawing? Web deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. This method utilizes both tensile and compressive forces, under high pressure, to achieve precise and consistent results while maintaining the thickness of the material. Web deep drawing is the process of forming a metal part from sheet stock, or a metal blank. Deep drawn parts achieve their shape by drawing metal into a cavity rather than by stretching or thinning over a die, so the original sheet thickness remains essentially the same from start to. Deep drawing produces shapes that are uniform and seamless, reducing potential weak points in the finished part. As mentioned, the punch and die setup is somewhat similar to a sheet metal cutting operation, such as punching or blanking. Web according to din 8584, deep drawing is a tensile compression metal forming process, which shapes a sheet metal blank as a hollow body open on the one side or of a projected hollow body to one with a smaller cross section, without intentionally modifying its. Deep drawing is a metal forming process used to create hollow, seamless parts with a depth greater than their diameter by drawing a sheet metal blank into a forming die with a punch. Web well, bless her heart! Two main factors will cause the punch in deep drawing to draw the metal into the die cavity, rather than shearing it. Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations. In this lesson, professor metal explains how deep drawing, multiple deep draws and hydroforming produce metal cups, cans, pans, domes and shaped metal products. Deep drawing involves stretching the metal blank around a plug and then moving it into a moulding cutter called a die.

What is Deep Drawing Process? mech4study

Deep Drawing Process A Overall Equipment B Specific S vrogue.co

Deep drawing of sheet metal

What is Deep Drawing Process? Mech4study

Introduction to Deep Drawing Process YouTube

best deep drawing process, by chris YouTube

Manufacturing Processes Archives Page 2 of 4 ElectricalWorkbook

What Is Deep Drawing ? Working Of Deep Drawing Sheet Metal Processes

Deep drawing Find suppliers, processes & material

Deep paintings search result at

Perhaps One Of The Biggest Misconceptions About Deep Drawing Is That The Metal Is Stretched Into The Part Geometry.

Deep Drawing Is A Frequently Used Process Of Forming Technology, Which Is Regulated In Din 8584.

Factors Affecting The Cost Of Deep Drawing Sheet Metal.

It Is Thus A Shape Transformation Process With Material Retention.

Related Post: