Deep Draw, Web drawing can be defined as a forming process in which the flow of metal into a cavity or over a post is controlled.

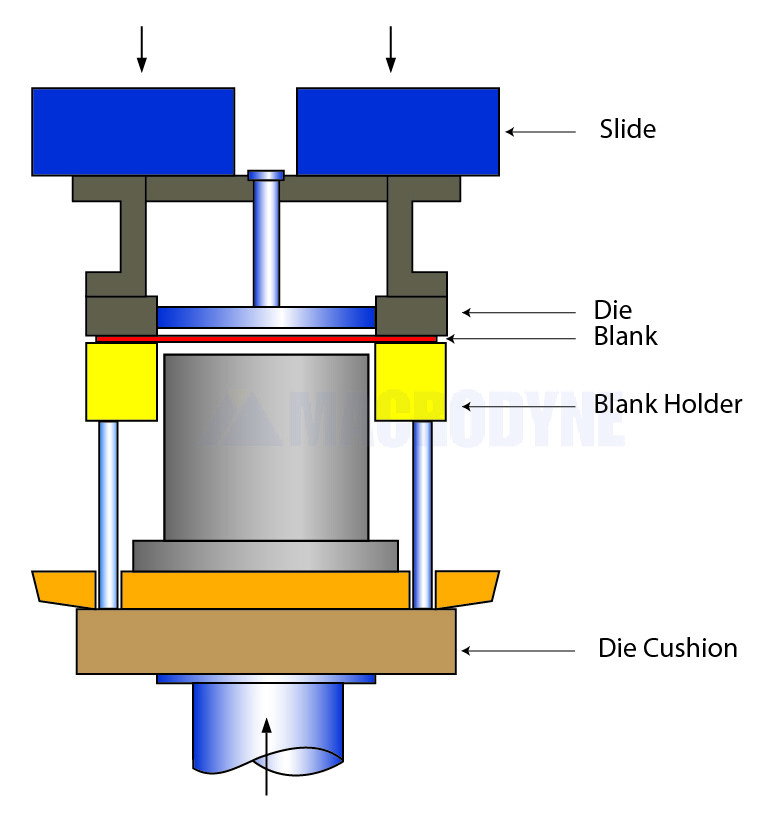

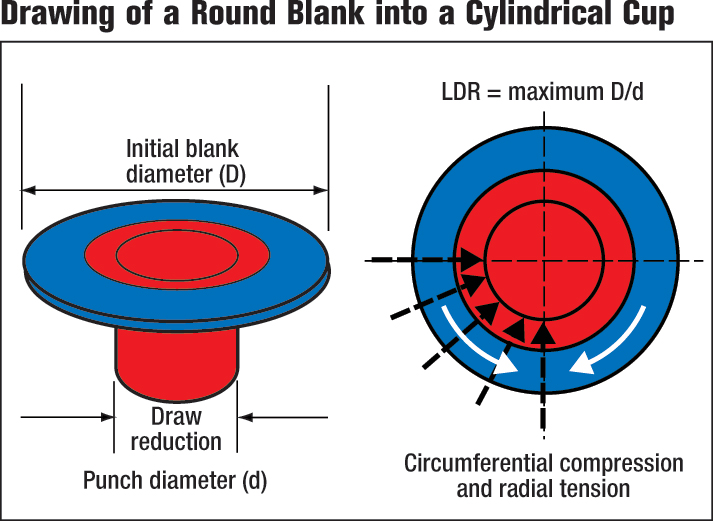

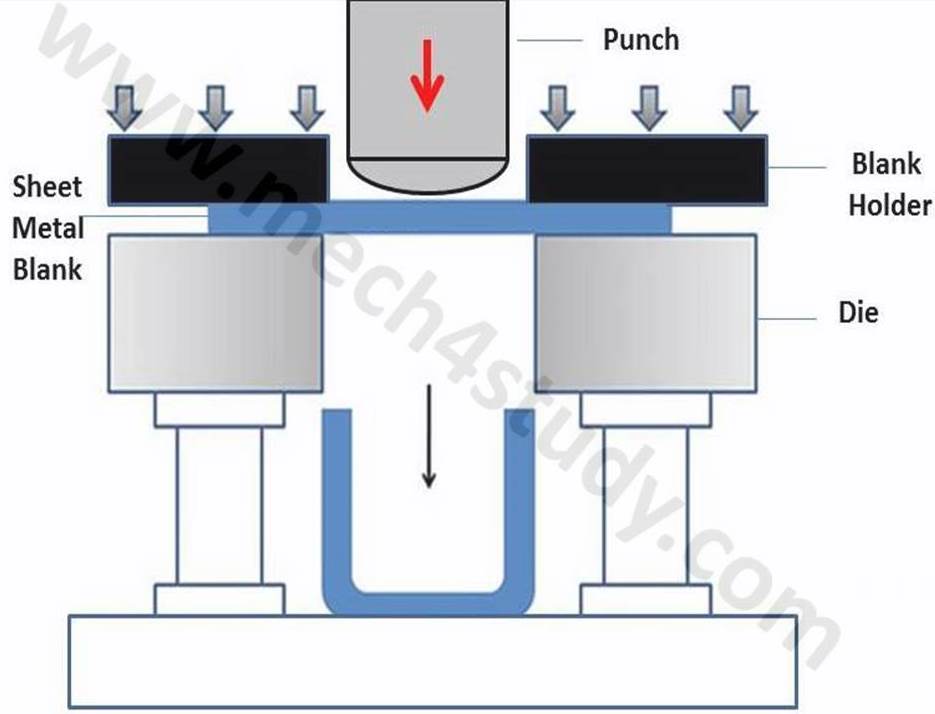

Deep Draw - Types of deep drawing parts. Web deep drawing is a processing method that uses a drawing die to press the flat blank into various open hollow parts or process the manufactured hollow parts into other shapes of hollow parts under the pressure of a press. Perhaps one of the biggest misconceptions about deep drawing is that the metal is stretched into the part geometry. The mold for deep drawing is been called deep drawing die. 1 what is sheet metal drawing? Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Web what is deep draw stamping? This process forms the metal into the final shape. Deep draw stamping is a specialized metal forming process that transforms a flat sheet of metal, commonly referred to as a blank, into a deep, hollow shape, or a “drawn” part. The process works by using a punch to force a sheet metal blank into a die; 1 what is sheet metal drawing? Types of deep drawing parts. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. The mold for deep drawing is been called deep drawing die. Perhaps one of the biggest misconceptions about deep drawing. Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations. Web drawing can be defined as a forming process in which the flow of metal into a cavity or over a post is controlled. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die. Deep draw stamping is a specialized metal forming process that transforms a flat sheet of metal, commonly referred to as a blank, into a deep, hollow shape, or a “drawn” part. Web deep drawing is a processing method that uses a drawing die to press the flat blank into various open hollow parts or process the manufactured hollow parts into. Types of deep drawing parts. Web what is deep drawing? Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations. Web deep drawing (in the context of sheet metal forming) is the process by which a flat sheet of steel is transformed into a deep (often complex) shape, whereby the flat sheet is “drawn in” from. Perhaps one of the biggest misconceptions about deep drawing is that the metal is stretched into the part geometry. This process forms the metal into the final shape. It is thus a shape transformation process with material retention. Web successful deep drawing is a combination of many important factors. The process works by using a punch to force a sheet. Perhaps one of the biggest misconceptions about deep drawing is that the metal is stretched into the part geometry. The mold for deep drawing is been called deep drawing die. It is thus a shape transformation process with material retention. Web drawing can be defined as a forming process in which the flow of metal into a cavity or over. The mold for deep drawing is been called deep drawing die. Web deep drawing (in the context of sheet metal forming) is the process by which a flat sheet of steel is transformed into a deep (often complex) shape, whereby the flat sheet is “drawn in” from the edges and “sucked in” to create a deep shape that otherwise may. Web deep drawing is a processing method that uses a drawing die to press the flat blank into various open hollow parts or process the manufactured hollow parts into other shapes of hollow parts under the pressure of a press. This process forms the metal into the final shape. Web successful deep drawing is a combination of many important factors.. Deep drawing is a metal forming process used to create hollow, seamless parts with a depth greater than their diameter by drawing a sheet metal blank into a forming die with a punch. We’ll delve into its foundational principles, the technical aspects, and myriad benefits. Perhaps one of the biggest misconceptions about deep drawing is that the metal is stretched. Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations. Perhaps one of the biggest misconceptions about deep drawing is that the metal is stretched into the part geometry. Types of deep drawing parts. Deep draw stamping is a specialized metal forming process that transforms a flat sheet of metal, commonly referred to as a blank,. Web what is deep draw stamping? 1 what is sheet metal drawing? Web deep drawing is a processing method that uses a drawing die to press the flat blank into various open hollow parts or process the manufactured hollow parts into other shapes of hollow parts under the pressure of a press. This article highlights only the most frequently violated design and build principles. This process forms the metal into the final shape. The mold for deep drawing is been called deep drawing die. It is thus a shape transformation process with material retention. Web successful deep drawing is a combination of many important factors. The process works by using a punch to force a sheet metal blank into a die; Perhaps one of the biggest misconceptions about deep drawing is that the metal is stretched into the part geometry. Deep draw stamping is a specialized metal forming process that transforms a flat sheet of metal, commonly referred to as a blank, into a deep, hollow shape, or a “drawn” part. Web drawing can be defined as a forming process in which the flow of metal into a cavity or over a post is controlled. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Deep drawing is a metal forming process used to create hollow, seamless parts with a depth greater than their diameter by drawing a sheet metal blank into a forming die with a punch. Types of deep drawing parts. Web what is deep drawing?

What is Deep Drawing Process? Mech4study

Deep Drawing 101 Macrodyne

Deep Drawing from A to Z MetalForming Magazine Article

What is Deep Drawing? Process, Diagram, Advantages & Applications

Deep drawing of sheet metal

Deep Draw Process for Precision Metal Components TransMatic TransMatic

What is Deep Drawing Process? mech4study

What Is Involved in the Deep Drawn Manufacturing Process? Hudson

What Is Deep Drawing ? Working Of Deep Drawing Sheet Metal Processes

best deep drawing process, by chris YouTube

We’ll Delve Into Its Foundational Principles, The Technical Aspects, And Myriad Benefits.

Web This Article Endeavors To Demystify The Intricate Domain Of Sheet Metal Drawing, Focusing Specifically On Its More Specialized Variant, Deep Drawing.

Web Deep Drawing (In The Context Of Sheet Metal Forming) Is The Process By Which A Flat Sheet Of Steel Is Transformed Into A Deep (Often Complex) Shape, Whereby The Flat Sheet Is “Drawn In” From The Edges And “Sucked In” To Create A Deep Shape That Otherwise May Not Be Possible Using Normal Metal Forming Techniques.

Deep Drawing Of Irregularly Shaped Panels Constitutes One Of The Most Complex Metalforming Operations.

Related Post: